What is Thermal Imaging?

Thermal imaging is the means by which humans can see the infrared portion of the light spectrum. “Well that is great great but I have no idea what that means or why it is important to my survey”!

How Does Thermal Imaging Work?

Every object gives off some amount of thermal radiation so thermal imaging is ideal for observing temperature anomalies that are abnormal in engines, electrical systems, tanks or even solid objects such as fiberglass, aluminum, steel or wood. For example when using a thermal camera in an engine room during a sea trial the surveyor can scan the cooling system of an engine such as a heat exchanger.

Left image is of a hull thermal image alone and the right image is the Thermal MSX® image.

These are two images taken of an engine during a sea trial. The image on the left is a heat exchanger on the port engine that is not operating properly. The heat exchanger on the right is the starboard engine which shows a bright red glow indicating engine coolant which is hot is flowing properly through the exchanger. This is an example of one advantage of using a thermal camera during a survey. By using the thermal camera the surveyor was able to detect an issue with the engine that needs corrected prior to the purchase.

Marine surveys are done using “non destructive” methods meaning the surveyor does not disassemble mechanical or electrical components for inspection. This can make the discovery of problems more challenging to even the trained surveyor. When inspecting an electrical distribution panel for example unless a surveyor checks each and every circuit there is no immediate way to discover an electrical short. By using a thermal camera a scan can be made of an electrical panel and any heat anomalies can be detected.

The image to the left is taken from the back of an AC electrical distribution panel. The image is showing a circuit that is radiating higher heat then the other circuits and the electrical wire is overheating. This may not be discovered using traditional surveying methods. The use of a thermal camera enables our surveyors to detect a finding such as this and possibly save the potential buyer from a costly repair or a potential vessel fire. Electrical issues can be hard to detect on a vessel. The use of a thermal camera can save money and time diagnosing electrical issues.

The image to the left is taken from the back of an AC electrical distribution panel. The image is showing a circuit that is radiating higher heat then the other circuits and the electrical wire is overheating. This may not be discovered using traditional surveying methods. The use of a thermal camera enables our surveyors to detect a finding such as this and possibly save the potential buyer from a costly repair or a potential vessel fire. Electrical issues can be hard to detect on a vessel. The use of a thermal camera can save money and time diagnosing electrical issues.

Why Don’t All Surveyors Use Thermal Imaging?

Thermal cameras and the training required to use them is an expensive investment. For many marine surveying companies the cost of such equipment is not practicle. The use of thermal cameras in marine surveying is limited to those companies willing to make the investment and obtain the training. At Sun Coast Marine Surveying and Consulting we want to insure we have the ability to provide the most detailed and accurate survey possible. Although rather new technology in marine surveying the use of thermal imaging is used extensively in the surveying of commercial aircraft hulls. Commercial airlines rely on trained thermographers to determine the safety of its aircraft, now our clients can have the same technology on marine vessels.

What Other Advantages Are There to Thermal Cameras?

There are a number of advantages to using thermal cameras when surveying a vessel. Some of these advantages are:

- It is real time which allows fast scanning and results. For example when on a sea trial scanning an engine under a load.

- No contact is needed. This keeps the surveyor out of harms way yet enables the surveyor to view areas normally difficult to examine while underway. An example again is when in an engine room during a sea trial, by using a thermal imaging camera the surveyor can scan the engines cooling system such as heat exchangers, manifolds, risers and exhaust systems. A turbo unit on a diesel engine is another high temperature component that can be inspected by using the thermal camera. Many of these components could not be inspected to the same degree without the use of thermal imaging. Because of thermal imaging, time is saved disassembling and troubleshooting a component or going through miles of wiring on a boat or yacht to find the problem. The thermographic image can find the problem quickly.

- Because of thermal imaging, time is saved disassembling and troubleshooting a component. When inspecting engines there is no way of knowing if a bearing failure is looming on a power steering pump, alternator or water pump. With thermal imaging the surveyor can detect a potential problem in a bearing by the excess heat detected on the thermal image.

- Thermal imaging enhances the marine survey report. Our company provides thermal imaging at no additional charge to our customers on all marine surveys. Thermal imaging on engines, transmissions, tankage, electrical systems, electrical components such as GPS and radar, and on vessel hulls and decks can determine if malfunctioning components, leaks, or delamination possibly exist within the vessel prior to closing the sale.

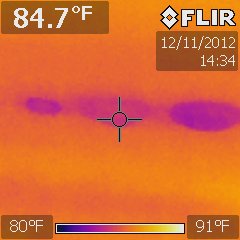

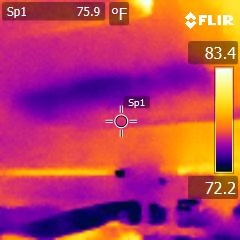

These two images are of a vessel hull and show indications of delamination in the hull structure. The advantage of using a thermal camera is these defects in the integrity of the hull are more easily discovered when surveying a vessel. Once the thermal anomaly has been discovered then we confirm the finding by using other tools such as a GRP 33 brand moisture meter and percussion hammer.

These two images are of a vessel hull and show indications of delamination in the hull structure. The advantage of using a thermal camera is these defects in the integrity of the hull are more easily discovered when surveying a vessel. Once the thermal anomaly has been discovered then we confirm the finding by using other tools such as a GRP 33 brand moisture meter and percussion hammer.

The tool we use when capturing thermal images is a FLIR® brand thermal camera which is similar in appearance and operation to a portable digital video camera. We have made the investment into a new line of thermal cameras that feature MSX® Thermal Image Enhancment. Not all FLIR® cameras have this technology. MSX® Thermal Imaging adds key details from the onboard visible light camera to the entire infrared image in real time. The result: an all-in-one thermal picture with numbers, labels, and other structural features intact so we can instantly recognize where the potential problem exists.

The tool we use when capturing thermal images is a FLIR® brand thermal camera which is similar in appearance and operation to a portable digital video camera. We have made the investment into a new line of thermal cameras that feature MSX® Thermal Image Enhancment. Not all FLIR® cameras have this technology. MSX® Thermal Imaging adds key details from the onboard visible light camera to the entire infrared image in real time. The result: an all-in-one thermal picture with numbers, labels, and other structural features intact so we can instantly recognize where the potential problem exists.

A special lens on the infrared camera focuses the infrared light emitted by all of the objects in view. With MSX® the camera has an additional lens which captures a digital picture and each image actually produces three seperate images. Using FLIR® Tools Software each image is then tuned and is viewed in three diferent formats.

1. Digital Image 2. Thermal Image Thermal 3. MSX®

The thermal MSX® image actually overlays the digital image over the thermal image to produce an image that is clear and easier to identify potential problems.